Carter Holt Harvey LVL edgeFORM®

edgeFORM® is laminated veneer lumber (LVL) specially prepared for use in concrete formwork applications as edge boards.

Features & Benefits

- Lightweight - Faster to install than traditional alternatives

- Painted bright red for moisture protection and easy identification

- Sourced from managed plantation forests – Available Forest Stewardship Council® (FSC®) certified (FSC® C007103) upon request

- Each stick is branded for ease of identification

- EWPAA certified with quality control procedures

Compliance

edgeFORM is manufactured using an ‘A’ Bond with less than 0.5mg/l Formaldehyde (equivalent to E0) emissions from the final product.

For quality assurance the edgeFORM range is manufactured with independent audit processes and product certification. Carter Holt Harvey LVL ensures that its wood is legally sourced from managed forests and offer FSC ‘Chain of Custody’ certified upon request.

edgeFORM at the time of dispatch from the manufacturing site has a moisture content of between 8-15%.

Suitable Applications

- Edge boards in concrete formwork framing projects

- Boxing for residential slabs

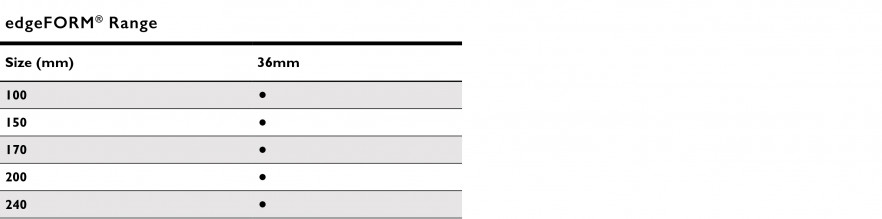

Range

Storage, handling and maintenance

For the longest durability and longest re-use potential edgeFORM should be:

- Stored undercover in well-ventilated area

- Handled and stacked with care to avoid damage

- Stacked flat clear of the ground on at least three evenly spaced bearers

- Re-seal cut edges with acrylic paint

- Wet members should have spacers between layers to allow to dry out

Software

Photo Gallery

Sds

Futurebuild LVL SDS untreated LVL

Chemwatch Material Safety Data Sheet for Futurebuild LVL untreated LVL

Brochure

Futurebuild Formwork Solutions Brochure February 2019

Our formwork solution consists of truFORM and edgeFORM and can be used as a complete solution or individually to produce a quality concrete finish.